TEAM MEMBERS

Sinan Payaslıoğlu

Yiğit Uysallı

What is a dumper?

A dumper is generally used in the back of trucks to transport and deposit materials( generally loose material).

A typical dump truck is equipped with a hydraulically operated open-box bed hinged at the rear, the front of which can be lifted to allow the contents to be deposited on the ground behind the truck at the site of delivery.

Our design serves the same purpose as a typical dumper, but we chose not to use a hydraulic system , as it would not be suitable to the course’s purposes. To use the dynamic equations that we have learned in the course, we used a system of two legs and two motors which will be further explained in the report.

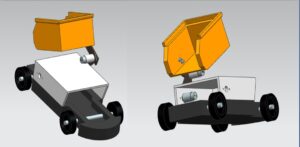

Isometric views of our design:

The parts:

First of all we paid nothing for the parts that we used except the motors and circuit elements. We used scrap parts we found in the lockers of the machine shop at the school, and from scraps of toy shops.

The base is an old remote control car’s chassis, the white part is an old cd-rom case, the legs are plexiglass(both 10cm long, 2 cm thick), and the dumper was first a plastic toy part but we had to change it to carton as it created too much moment for the motors to handle.

The motors are DC geared 12V motors. We had to try several different ones with different rpms to get better results, and because some had problems in their reduction gear system.

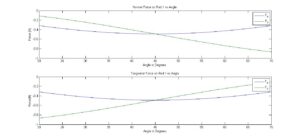

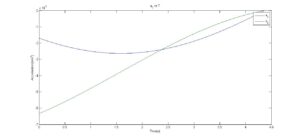

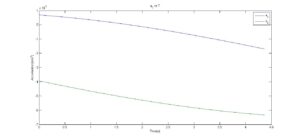

The kinematics:

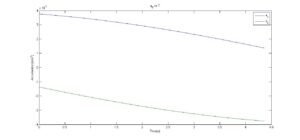

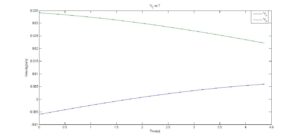

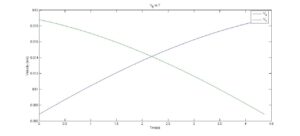

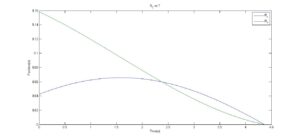

The purpose of the dumper we built is to first rise, then dump. During the rising process the dumper needs to be parallel to the ground, so while the motor at point A turns clockwise, the one at B has to turn counter clockwise at the same time. We managed this by designing the electrical circuit properly(with differentiable resistances).