TEAM MEMBERS

Hüseyin Mert Erdoğan

Ege Uslu

1.1 Aims of model

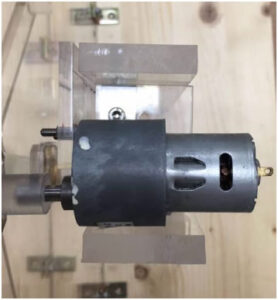

This is the report from MECH206 Dynamics report. This project brings us together in many concepts from math and physics. MatLab, NX and Tracker we enhanced our skills in computer science engineering. Our model converts continuous rotational motion into periodic circler motion.

1.2 Materials

Materials that we used;

Plexiglassplastic sheet in its colorless grade is as clear as the finest optical glass but is lighter in weight, has higher breakage resistance and can easily be fabricated into shapes limited only by the designer’s imagination. The unexcelled versatility of Plexiglas sheet, its optical clarity, ease of fabrication, its light weight and breakage resistance compared with glass and the variety of sizes, thicknesses, patterns and colors available, allow virtually unlimited use for the unobtrusive protection and display of valuable works of art.

PolylacticAcid(PLA) is primarily created using renewable or green sources such as sugar cane, starch and corn. As a result, it can easily be recycled. It is used in most additive manufacturing processes that design 3-D models and prototypes through plastic-based materials.

PARTS: Plexiglass:

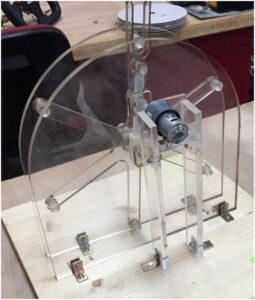

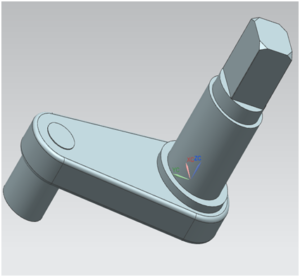

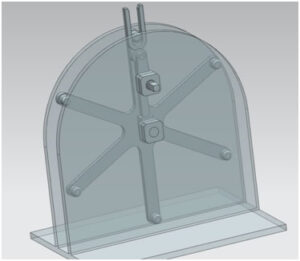

Crank: We have produced this part by first 3D modeling it in NX and then by laser cutting we produced the middle part of it. The shafts were made by turning machine and tightly fit inside the holes which are in the middle part. This part of our design turns another component in our design which is named “coullise”

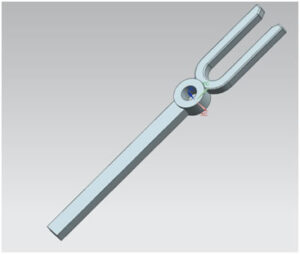

Coullise: This part of our design was produced by laser cutting after modelling it in NX. The thing it does is basically turning the pins on the disk.

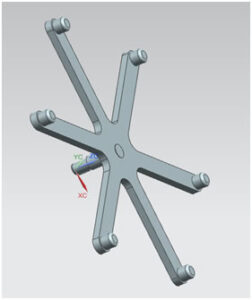

Disk: We have first modelled this part in NX and then we have cut the base of the disk by laser cutting process. The 6 pins on it were produced by turning machine and were tightly fit inside the holes on the disk. The purpose of this part is basically to transform the uniform rotational motion of the crank into periodic motion.

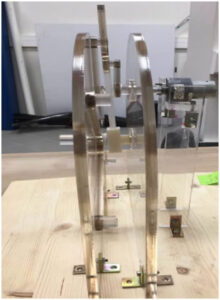

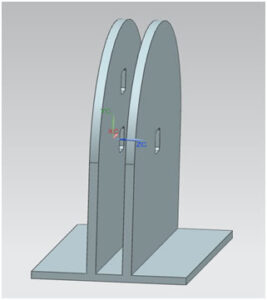

The side supports: They were basically produced by laser cutting and their job is to keeep the mechanism on a vertical position so that it can function. (This part was not in the design that we took as reference)

Polylactic Acid (PLA, Polylactide):

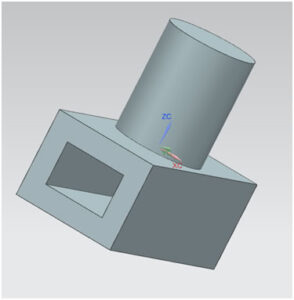

Runway: We have produced this part by 3D printer. It keeps coulisse in it’s place so that it does the desired motion.

ASSEMBLY

The mechanism itself

The design that we came up with so that the mechansim could stand vertically