TEAM MEMBERS

MÜGE KORKMAZ

DENİZ AKBAŞ

HÜSEYİN DENİZ AKSOY

CONTENT

Introduction : The part that we are essentially going to discuss about what is a scissor mechanism and which fields is this mechanism used so far.

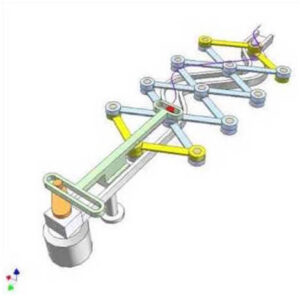

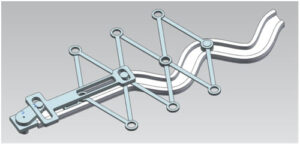

CAD Drawings : The part that we actually draw the mechanism on both Siemens NX and SolidWorks in order to manufacture the particles of mechanism.

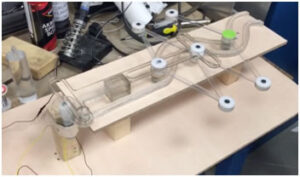

Manufacturing Process :The part that we manufactured our mechanism by using our CAD Drawings in laser-cutting machine. We used plexiglass as a material. We manufactured the pins of the scissors which is thermoplastic by using turning machine. We used silicone in some of the particles to make them stick with each other.

Calculations :The part that we used the equations that we learned during the semester in Mech206 course.

Matlab Simulation: The part that we established a simulation for our mechanism in Matlab by using the calculations and writing a code for the system that we observed previously .

Matlab Analysis :The part that we had datas about our theoretical values by using our matlab codes.

What is a scissor mechanism?

It is basically a mechanism that uses linked, folding supports in a criss-cross pattern. It is actually a very good example of converting rotation motion into linear or any desired path. In our case the system is composed of multiple links connected to a rotating shaft and when it rotates the scissors follow the pattern that we decided.

We outlined our design process into 2 steps.

STEP 1: CAD DRAWINGS

After our project is given to us firstly, we have started to draw the parts of the scissor mechanism. We chose Siemens NX as drawing program. Mostly drawing part was easy however we had difficulties while drawing the sin path. We have decided to draw sin path in SolidWorks and we solved the problem by changing the program.

STEP 2: MANUFACTURING PROCESS

In manufacturing process, by the helps of CAD Drawings we selected our material as plexiglass and we used the laser-cutting machine for cutting the plexiglass. Then we manufactured the pins by using turning machine, which are thermoplastic as a material. We have used silicone in order to stick plexiglass with each other. In order to attach motor into the system we manufactured a head, which is also thermoplastic and after we attached the parts which each other according to the simulation that was given to us in the first lecture, we are done.