TEAM MEMBERS

CANER ÖMER PAR

YİĞİT GÜRMAN

Main Parts:

Aluminum (failed):

We first decided to make our project from aluminum. We gathered our material and went to a machine shop that has milling machine. We asked technician to teach us how to use it and then we started to use it. He has not got any other job so he taught to use it and let us do the rest. Because we are not professional to use milling machine, it took seven hours to finish it. Also there were many details that we did wrong and we asked technician to fix them. For example, we forgot to spill oil to a component while milling and because of heat it started to bend. Also when we look at the components, they were not so smooth and there were many deformations. At that time, we started to think about how we can get rid of friction. In our project, the surface should be frictionless. As we scared, when we combine the parts, it was hard to move them because of friction and some deformations. The parts stocked and the motor hardly moved them. At last, we decided change our material and chose plexi glass.

Plexi Glass:

We went to a glass shop and asked them to manufacture our parts with their laser cutting machine. We gave them our technical drawings and it was so easy to process according to aluminum. The parts were ready in ten minutes. The surface of the parts was so smooth so we were sure that this time it will be successful. Note: Plexi glass was easy to process but we have no contribution to the processing. So we are glad that we at least tried to manufacture the parts from aluminum and learnt how to use milling machine.

Motor:

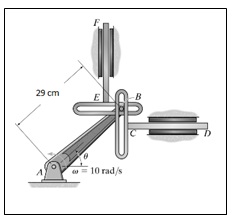

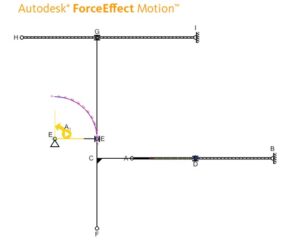

We used Servo motor (5V, 2A) because we need a 90 degree movement. It is easier to control a servo motor rather than a DC motor. If we used a DC motor, we must have used gear system or a belt system. However, with Servo motor we can easily control it from Servo motor computer controller. Additionally, our project does not need much power so the Servo motor we used was cheap and enough but a DC motor with the same price can produce much more power than a servo. So if we needed much power, it would be more economical to use a DC motor. Servo that can provide high power can be very costly. Our project, which is a two-directional sliding mechanism, is used to convert rotational motion into translational motion and also rotary into linear motion. Real life examples are:

– Laser Cutter

– Milling Machine

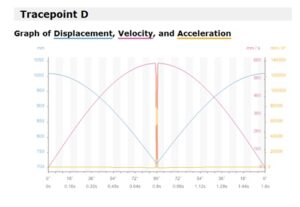

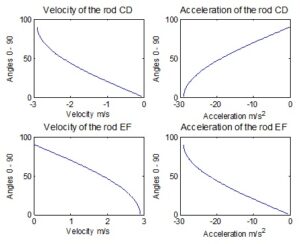

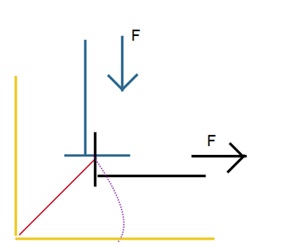

For example, in order to create an arc or a circle the tip moves on the x and y directions. In order to make such a movement both the arms on the x and y directions makes the displacements calculated as in our project. Also in order to regulate the speed of the tip, we again use the calculations made in our project. Also the acceleration can be regulated in this way. Another place where it can be used is, to transfer a force acting in y direction into the x direction. This is explained by using this figure: As the force on the y direction is acting downwards, the red arm makes a rotational motion about a fixed point. During this action the black arm on the x direction moves to the right with the same “F” force magnitude (assuming non friction surfaces). So the force acting on the y direction is transferred to the x direction.