KAAN KESGİN

NİDA TUNA

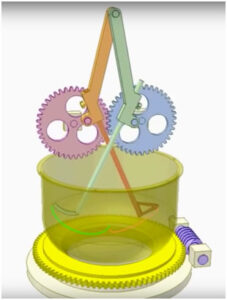

A mixing machine is a mechanical system that is used for mixing various liquid -liquid, liquid – solid and/or solid – solid (mostly powders) systems. Mixing machines that are used for mixing foods are most commonly seen examples of such mechanisms. Industrial mixing machines that mix significant amounts of chemicals (cosmetics, adhesives etc.) also exist. For such mechanisms rotational motion is almost inevitable, and for an effective design rotational motion is usually first approach considered by system designers. These systems mostly consist of a motor, various gears and links.

In order to manufacture and analyze such a system, computer aided design is used for designing parts that compose the system, computer aided manufacturing is used for assisting the manufacturing process of designed parts and computational tools such as Matlab is used for analyzing corresponding dynamic equations, in addition software Tracker is used for investigating the actual system that is running in real world.

– CAD process

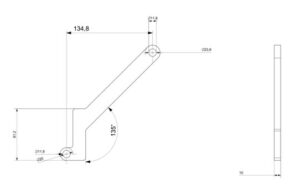

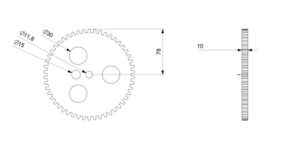

Looking at the motion video found on https://www.youtube.com/watch?v=6ktLcEOzY9o parts are reverse engineered. Using a ruler parts are estimated proportionally on the video. Once the parts are designed via Siemens NX they are drafted for further calculations in dynamic analysis step.

CAM process

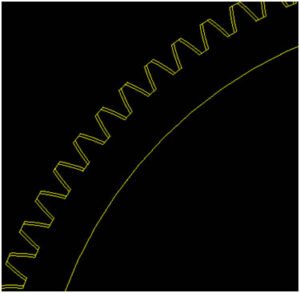

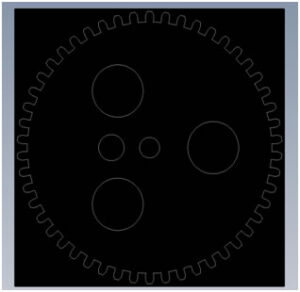

Parts that have constant cross section with respect to one axis are manufactured using Plexiglas and a laser cutter (image 1&2). .prt files that is default format for NX are exported to .dxf format which is the appropriate file format for laser cutter.

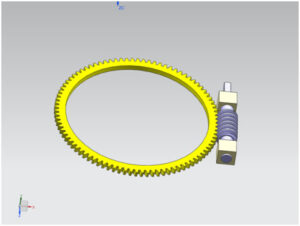

Remaining parts which were not possible to manufacture via laser cutter (worm&worm gear) are manufactured using a 3D printer (image 3&4). Those parts being .step format are exported to .stl format which is appropriate format for additive manufacturing.