Genco Darcan

Ömer Koyuncu

This is the report of our Mech 206 term Project, the Rotation to Translation Mechanism. We started our Project with the guidance of a video of the mechanism. It is based on

Two Upper Plates

Four Circular Gear Plates

Shaft

Small Bracket Part

Big Bracket Part

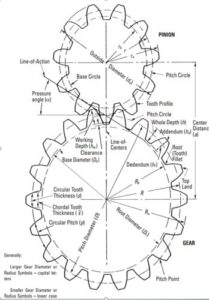

Two Identical Spur Gears

We made a gantt chart for a well-planned success. First we started with the CAD Design / Motion Analysis and Literature survey. After them, we focused on the theoretical analysis and we manufactured the parts that we decided. After we discussed on the results with our TA Enes Yiğit, we measured the experimental values and discussed between the experimental and theoretical results.

The working principle of mechanism is converting rotational motion to translational motion. We used eccentric gears. Eccentricity states “the distance of the geometric center of a revolving body from the axis of rotation”[1].In other words, an eccentric rotor is one in which the shaft centerline does not line up with the rotor centerline. This results in more weight being on one side of the rotating centerline than the other and causes the shaft to wobble in an irregular orbit. This is inherently unstable and can be the source of troublesome vibration.

At manufacturing, we tried to use both Plexiglas and Metal Sheets for experimenting procedures with different materials. We made our gears from Plexiglas and other parts from metal sheets. We cut metal sheets and Plexiglas in different laser machines, and used turning machines, milling, and surface grinding machines.