TEAM MEMBERS

Nazım Onur Yılmaz

Koray Tütüncü

Our project is called grab bucket, which is a bucket with hinged jaws or teeth that is hung from cables on a crane or excavator and is used to dig and pick up materials. The bucket itself is divided into two equal halves that are connected with hinges. The overall appearance is almost like that of a human jaw that opens and closes.

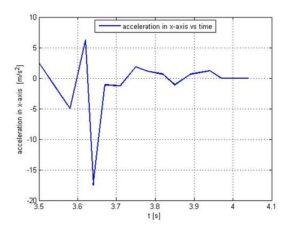

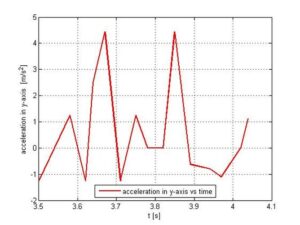

The aim in this project is to calculate the acceleration and the force on the edge of the bucket. For this cause we first made assumptions because without assumptions our calculations wouldn’t be possible or it would become a nightmare. After we made the assumptions we made the theoretical calculations. In those calculations we mainly used what we learned in Mech 206. Then we took experimental measurements using video camera, load cell and Matlab. We were lucky that one of our group members (Nazım Onur Yılmaz), took Mech 307 (Numerical Methods for Mechanical Engineering) which helped us making Matlab calculations for the experimental measurements. After the experimental measurements and theoretical calculations we compared them to see the accuracy of our data. Some errors are obtained during this comparison due to the assumptions we made and some technical difficulties.

During this project some assumptions were made. Firstly we assumed that our motor is a dc motor although it is a servo motor, which needed a very complicated approach to make calculations that requires higher knowledge of engineering in dynamics. Because dc motors have approximately constant “ω” the derivative of it, which is “α”, had to be zero. Also the “r” vector’s dimension changing with time due to the change in Q but it is almost minimal and we took it as a constant. Finally we also assumed that there is no loss of energy in gears.

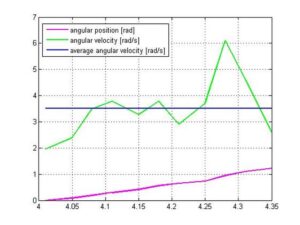

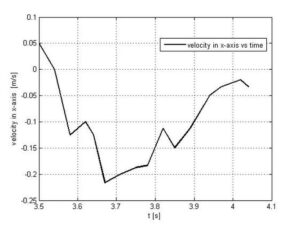

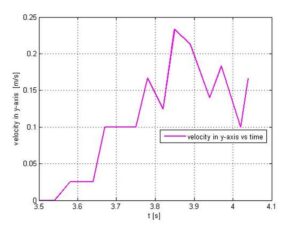

Our motors “ω” was not constant and also “ω” was not included in the specifications of motor, we had to calculate it with data from the video. First we took a full cycle video clip of our grab bucket, in which we used protractor. Video is divided frame by frame to measure the change in angle with time. Data that we took from our frames were used in Matlab program for the purpose of changing the angular position to angular velocity by taking the derivative of angular position with time. After we find the angular velocity we took the average and come up with the average angular velocity of the motor so that we could use it later in our calculations.