TEAM MEMBERS

Naz Altekin

Beril Şahin

Lifting mechanisms are used to lift objects. There are many types of lifting mechanisms available, such as rotating joint systems, elevators and linkages. For our Mech 206-Dynamics project, we built a lifting mechanism with rotating joint system. The basic principle of this mechanism is to convert rotational motion into linear motion. Despite its relatively easier mechanism, it is not usually preferred because of its lower load capacity.

In our system a worm gear rotates at a constant rpm, the rotational motion is then converted to linear motion of the racks. Linear movement of the racks causes the gears to rotate and therefore, lifting of the platform occurs. Design, manufacturing and material selections will be explained in the later sections and the system will be analyzed with dynamic equations and possible errors will be evaluated.

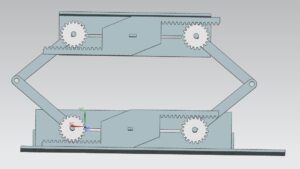

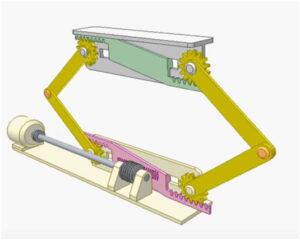

Siemens NX and Solidworks are used to design the components of our system. The system consists of 4 gears, 2 racks, 1 middle part and parts for bottom and the platform. As shown in Figure 1. Worm gear in the original design is replaced by a stud bolt on the design, because finding or manufacturing the worm gear was very difficult. Therefore, some variations are made on how the system works.

After the manufacturing process, our design proved to be not balanced and functional so we had to make some major changes. First of all, we built a box around the bottom rack and the upper rack. In order to prevent undesired motion of the gears, we used two racks instead of one in both upper and lower parts. To fix the box around the bottom parts we had to use another stud bolt attached to the box in the same direction with our main stud bolt.