UGURCAN TEMUR

K. AYBERK KOCYIGIT

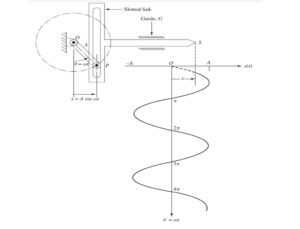

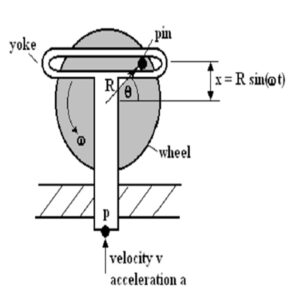

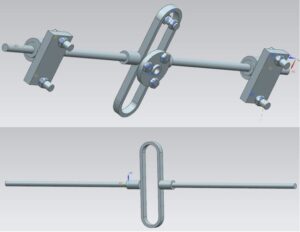

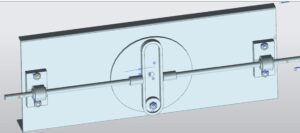

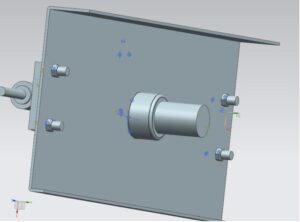

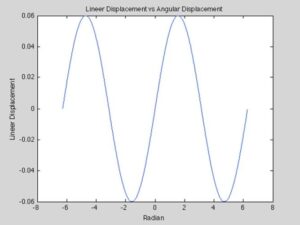

The Scotch Yoke is a mechanism that converts rotational motion to linear motion. The piston or other reciprocating part is directly coupled to a sliding yoke with a slot that engages a pin on the rotating part.

Applications:

The Scotch Yoke is most commonly used in control valve actuators in high pressure oil and gas pipelines.

A Shaper (which is not commonly used today) uses a Scotch yoke which has been adjusted to provide a slow speed forward stroke and a faster return.

Scotch Yoke is also used in various engine types, such as Bourke engine, SyTech engine, and many hot air engines and steam engines.

Advantages of Scotch Yoke:

High torque output with a small cylinder size.

Fewer moving parts.

Smoother operation.

Higher percentage of the time spent at top dead center (dwell) improving engine efficiency.

Disadvantages of Scotch Yoke:

Rapid wear of the slot in the yoke caused by sliding friction and high contact pressures.

Lesser percentage of the time spent at bottom dead center reducing blow down time for two stroke engines.