Tuana Demir

Selin Alkan

Doruk Pelin

INTRODUCTION

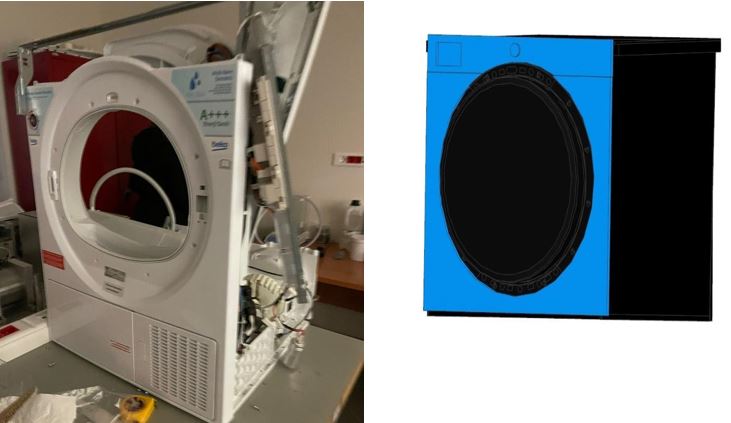

OUR PROJECT-USAGE OF THE DRYER-OPERATION

Our project is a dryer machine which is used for drying clothes. There are 10 main parts of our machine. These are metal drum, air intake, a fan, electric motor, heating element, holes, belt, clothes, lint filter and vent hose. Operation of the dryer is as follows, a resistance is created by sending an electric current through the coil. Electrons build up due to the resistance so that the energy (heat) is being created. The heat is transferred to the surrounding and forced through the dryer by a blower fan. These metal coils become very hot due to building up of electrons. Thermostats and thermal fuses are used in dryers in order to regulate the temperature inside the dryer. These parts play an important role in safe operation of the appliance and prevention of overheating.

DISASSEMBLY

We used different types of measurement tools during the disassembly process. The most used tool is the compass. We used this tool to measure the length, width, diameters and little detail parts. We also used a ruler, tape measure and sticks. We confront some challenges during disassembly and measurement processes. Some parts were connected to each other very hard thus, we used multiple screwdrivers and various tips to separate them. In the measurement part the most challenging part was measuring the spaces in the pieces. It was not easy to use compass or other tools to measure it, that is why we used measured sticks.

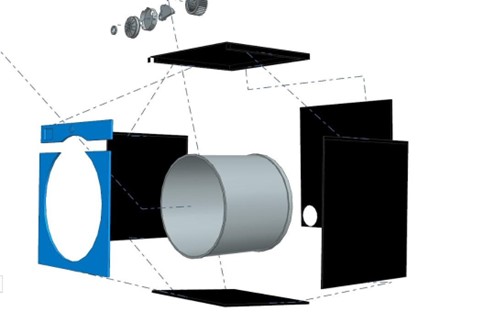

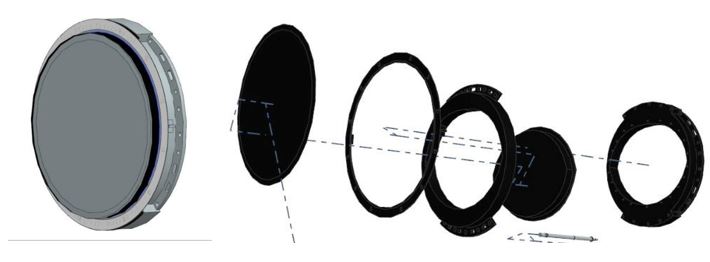

EXPLODED VIEW

Our group has 31 parts in total. Our machine is assembled in 3 main parts. Firstly, the door part is formed from 11 parts. Secondly, the shaft and motor part which are formed from 11 parts. Lastly, panel part of the dryer which is formed from 10 parts.

PANEL PARTS

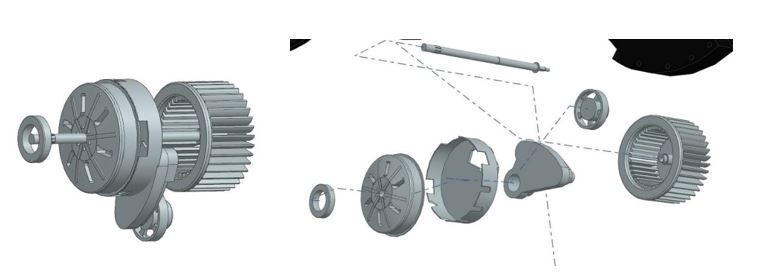

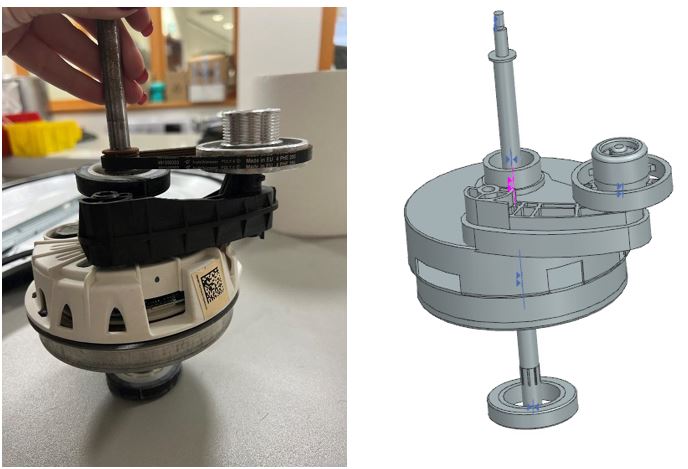

SHAFT AND MOTOR PARTS

DOOR PARTS

COMPARISONS

Shaft and Motor

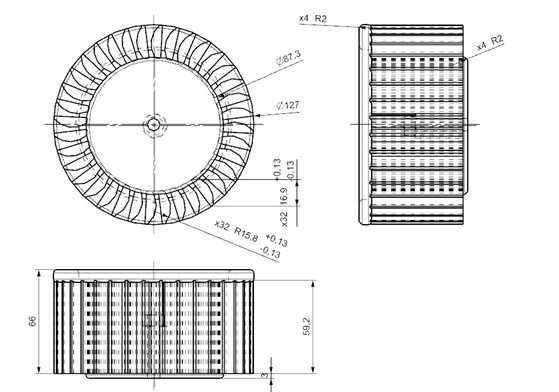

Blower Wheel

NX COMMANDS

While modeling our parts in Siemens NX, we used various commands. Some of them are project curve, pattern and mirror to provide faster sketching and modeling, edge blends for softer look, draft to add inclined surfaces.

DRAFTING AND TOLERANCES

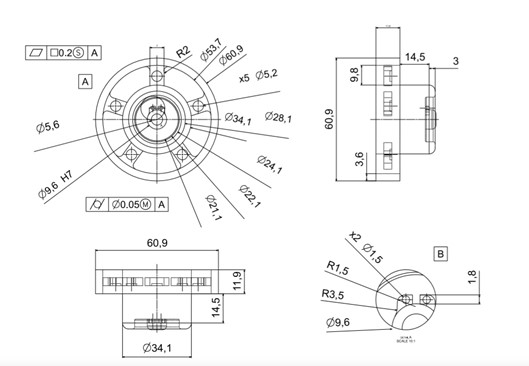

Motor Part

Blower Wheel

Draft and Tolerance Comments

We chose these drafts because the motor, shaft and blower wheel are the 3 most important parts for the motion of the machine and the door cap is one of the crucial part for the outer side of the dryer. There are dimensional tolerances according to the material that is used for the part (H7), surface tolerances (Ra 0.6) to indicate the surface features. Also, there is flatness tolerance (0.2) from the form type of tolerance and parallelism (0.3) from orientation tolerance type. Lastly, cylindricity tolerance (0.05) type to make sure about the straightness and roundness along the axis.