Mert Kılınç

Berk Ömürlü

Gökhan Ulutaş

Bircan Nuhoğlu

Arda Oruç

Introduction

-What is your project?

- Our project is Gearbox. We used model named “FORD ROCKET (TYPE E) 4-SPEED GEARBOX” as our part.

-What is it used for?

- The gearbox is a type of speed change device with numerous uses in the speed change of machines mostly in automobiles. It achieves the desired speed change effect through the meshing of big and small gears. A tiny gear is fitted on the gearbox’s high-speed shaft, and a large gear is mounted on the low-speed shaft. Acceleration and deceleration can be accomplished by the transmission and meshing of the gears. This specific gearbox model is used in four different Ford models: Capri, Sierra, Escort and Cortina.

-How does it operate?

- A gearbox is used to increase or decrease speed. The speed function will therefore be the inverse of the torque output. The torque output will increase if the enclosed drive is a speed reducer (speed output is less than speed input), and it will decrease if the drive increases speed. Gearbox is a part that transmmits power from the engine to the tires.

Disassembly

-How did you measure the dimensions of your part?

- We measured the dimensions with caliper and also for some longer parts we used simple rulers.Did you face any challenges during the disassembly or measuring the dimensions?

- Since gearbox is a part that always works in high speeds and high temperatures, it is a very stable part. Even tough our part is over 40 years old, it was still working before disassembly. Being durable is good for car, however it made our disassembly process very hard. We had two main problems which are.

1) Place to disassemble, since our part is very big, heavy and greasy, we couldn’t disassemble it in our dorm rooms. Being greasy made our disassemble process annoying, and we didn’t wanted to mess the place we are working on.

2) Gearbox is a very complex part that needs a wide range of tools to disassemble. Disassemblying it was like solving a puzzle and we couldn’t figure out how to solve it multiple times. Also that caused our disassembly process to last really long.

-How did you solve those problems?

1) Muzaffer Abi helped us on this problem, without his help we couldn’t find a place to disassemble. At first he suggested us to change our project just because of this reason but we said we are ready to get our hands dirty. He gave us a table in his workshop and laid carboards and cloths on it to keep the grease off the table.

2) Just like our first problem, Muzaffer Abi provided tools and helped us solve some problems up to a point, but even he couldn’t solve how to disassemble some of the parts. After that we called someone from industry who is specialized in gearboxes, thanks to him and some guides from internet, we were able to disassemble our part.

Exploded View

Exploded View-How many separate parts does your object contain? How many parts did you assemble in the assembly file?

- We had a total of 63 parts and 43 of these parts were unique.

Part Comparisons and NX Commands

• The pictures on the right side are real parts, on the left side we have the rendered versions of them.

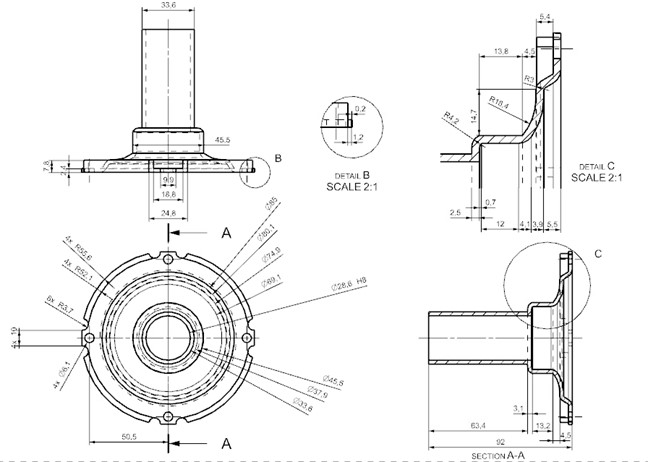

Drafting and Tolerances

Drafting and Tolerances Finite Element Analysis

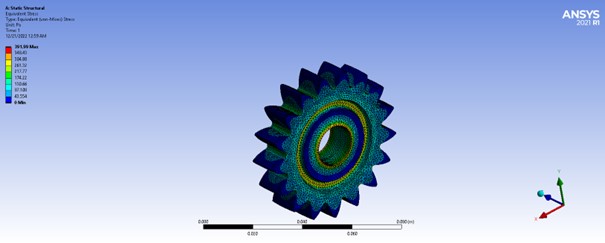

Finite Element Analysis -We simulated the reverse gear in ANSYS as shown in Fig. 1. This simulation is important since reverse gear exposure a lot of stress during the transmission of the revolution to the motor and that stress may cause a critical damage to the gearbox. Our analysis type is structural analysis and we used stainless steel as our material. We fixed the inside part of the gear and rotate added rotational velocity with various values (10 rad/s, 15 rad/s, 20 rad/s, 25 rad/s, 30 rad/s, 35 rad/s, 40 rad/s). The accumulated maximum von Mises stresses for each rotational velocity is shown in Fig. 2 and 3rd degree polynomial of the stresses are shown in Fig. 3. According to our analysis result, maximum von Mises stress occurred around the hole.

Additional Work

Additional Work- We made shifting motion of the gear in NX, it took some research and time, but we believe the results were satisfying.

- We have all 4 gears and shifting motions below.