TEAM MEMBERS

Haluk Okan Sözüer

Güngör Alp Şenuslu

Sıtkı Burkay Göralcan

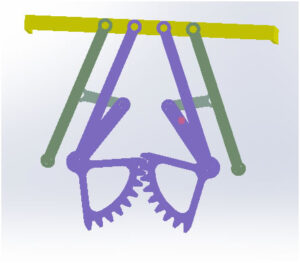

In this project we produced an extendable table which can be used easily. The process of this project was not easy because that we were making a prototype thus the parts were small also the materials that we used were limited. At first sight it seems a simple mechanism with one wheel which assembled to two other main links, these three parts are the parts that gives our table motion.

When we were manufacturing our project we chose to use plexiglass so it can be easily produced and it doesn’t cost much. The difficulties that we faced about plexiglass are that the material is likely to stick with special glue easily so during the assembly process it was hard for us to deal with that. For every linkage connection we used bearings because in our mechanism almost every part has an angular motion so we obviously needed a bearing to give those parts rotation.

The project can be easily designed, it can be manufacture untroubled with professional equipment and qualified staff.

The design part was the part that we struggled less than according to other processes of the project. The system is very simple as you can easily observe that there are three linkages that can be designed at SolidWorks with almost three simple steps. The wheel was the harder part to design among other parts.

We decided to take the holes at the yellow covers as our reference point so we can be manage the big linkages angle. When we have the angle of the big linkages the rest was building on that step we first assembled the wheels to the bottom with a bearing inside of it , we proceed with assembly using middle linkage .

We assembled the little green linkage to the middle purple one with taking the reference of the holes of the table which goes upward when the motion starts. So after we completed the left side of the assembly the right side was just a symmetric of it so that part was not difficult.