TEAM MEMBERS

Beri Haravon

Batu Çalışkan

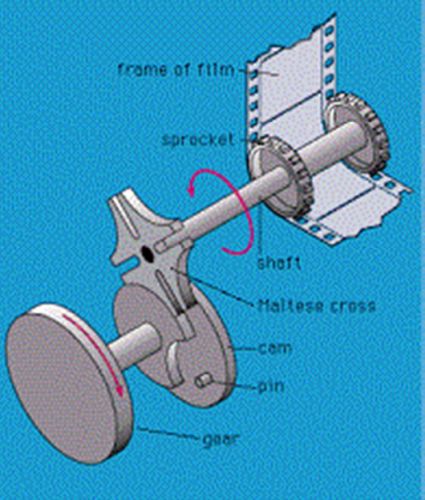

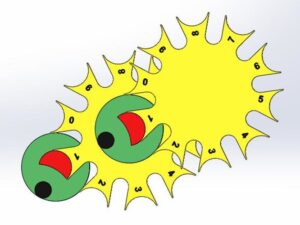

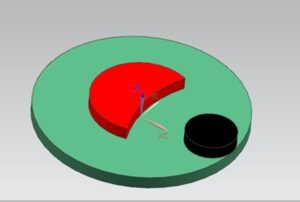

The Geneva drive is a gear mechanism that translates a continuous rotation into an intermittent rotary motion. The rotating drive wheel has a pin that reaches into a slot of the driven wheel advancing it by one step. The drive wheel also has a raised circular blocking disc that locks the driven wheel in position between steps.

Advantages

Geneva’s may be the simplest and least expensive of all intermittent motion mechanism. They come in a wide variety of sizes, ranging from those used in instruments, to those used in machines tools to index spindle carriers weighing several tons. They have good motion-curve characteristics compared to ratchets, but exhibit more “jerk,” or instantaneous change in acceleration.

The Geneva maintains good control of its load at all times, since it is provided with locking ring surfaces, as shown in fig, to hold the output during dwell periods. In addition, if properly sized to the load, the Geneva generally exhibits very long life (about 20 years).

Disadvantages

The Geneva is not a versatile mechanism. It can be used to produce no less than three, and usually no more than 18 dwells per revolution of the output shaft. Furthermore, once the number of dwells has been selected, the designer is well locked into a given set of motion curves. The ratio of dwell period is also established once the number of dwells per revolution has been selected. Also, all Geneva acceleration curves start and end with finite acceleration and deceleration. This means they produce jerk.