Çağın Kudun

Efe Temel

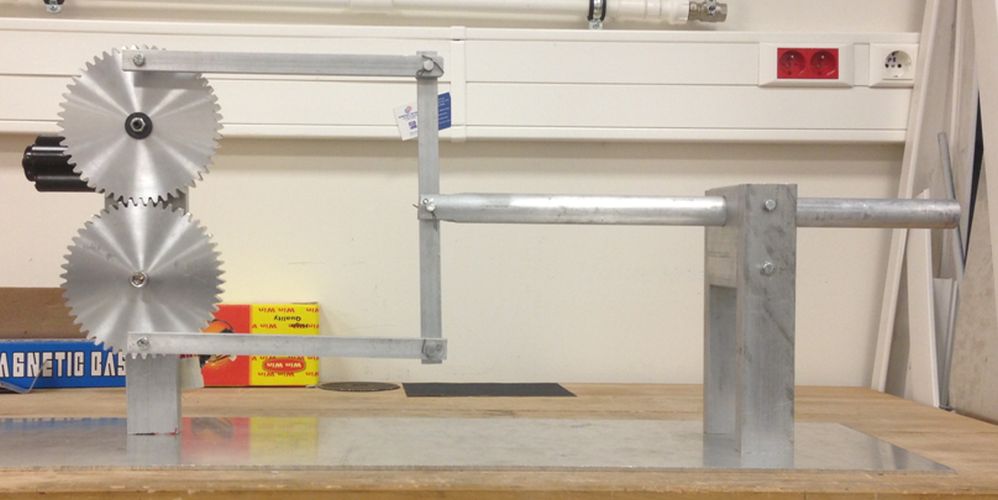

Our goal in this project is to design an alternating reciprocating mechanism, build it, and then make the necessary calculations to model the motion.

We had a four step approach to this project; Research, design, manufacturing and analysis.

We first familiarized ourselves with the concept of reciprocating motion.

Reciprocating motion, also called reciprocation, is a repetitive up-and-down or back-and-forth motion. It can be found in machines such as reciprocating engines and pumps. Crank is used to convert circular motion into reciprocating motion, or conversely turn reciprocating motion into circular motion.

An example can be an internal combustion engine.

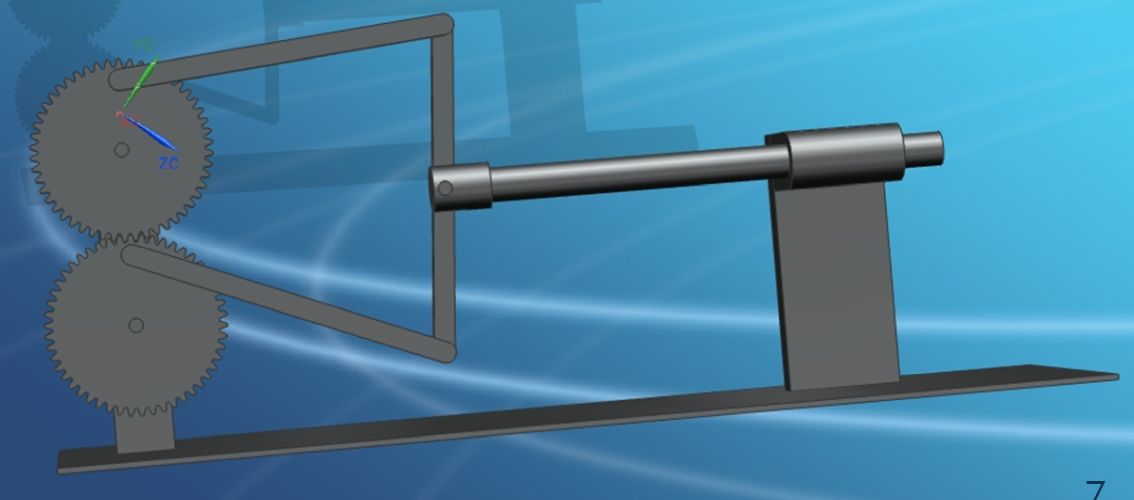

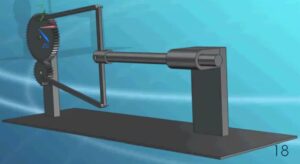

First part of our design was to decide the geometry.

We then proceeded to decide on the materials used. We agreed on aluminum because of a few reasons;

-

- It is available to us, and it is affordable.

- It is ductile, and relatively strong.

- It is easily machinable.

- We have experience working with aluminum.

- We could not communicate properly with people selling Plexiglas.

Aluminum does have its downsides though;

-

- It is heavy.

- It is more expensive than a few other materials we could have chosen.